Laminated tubes offers a competitive edge in the market and are used across the globe for packaging in personal care, food, pharma and industrial applications.They are manufactured from multi-layer laminate foil with the use of aluminium or plastic barrier that is inserted between the inner and outer layers of the tube.

With excellent barrier properties, laminated tubes give a cost effective solution to help increase product shelf life. Laminated tubes represent an easy, hygienic and safe method of packing, that provides efficient barrier against leakage of volatile substances and protection against UV rays as well.

With excellent barrier properties, laminated tubes give a cost effective solution to help increase product shelf life. Laminated tubes represent an easy, hygienic and safe method of packing, that provides efficient barrier against leakage of volatile substances and protection against UV rays as well.

LAMINATES

Our standard laminates are composite materials made from LLDPE that form the core barrier of the tube body. They help keep contents fresh and safe with multiple layers of foil. Laminates also help a product catch the customers eye from the shelf, with their various available finishes and design possibilities.

ALUMINIUM BARRIER LAMINATES (ABL)

The barrier against leakage of volatile substances from tube contents and against oxidation of tube contents is formed from aluminium foil, which is also the carrier of laminated layers of plastic material. This barrier feature gives an advantage to the laminated tubes over plastic tubes that do not possess such a feature.

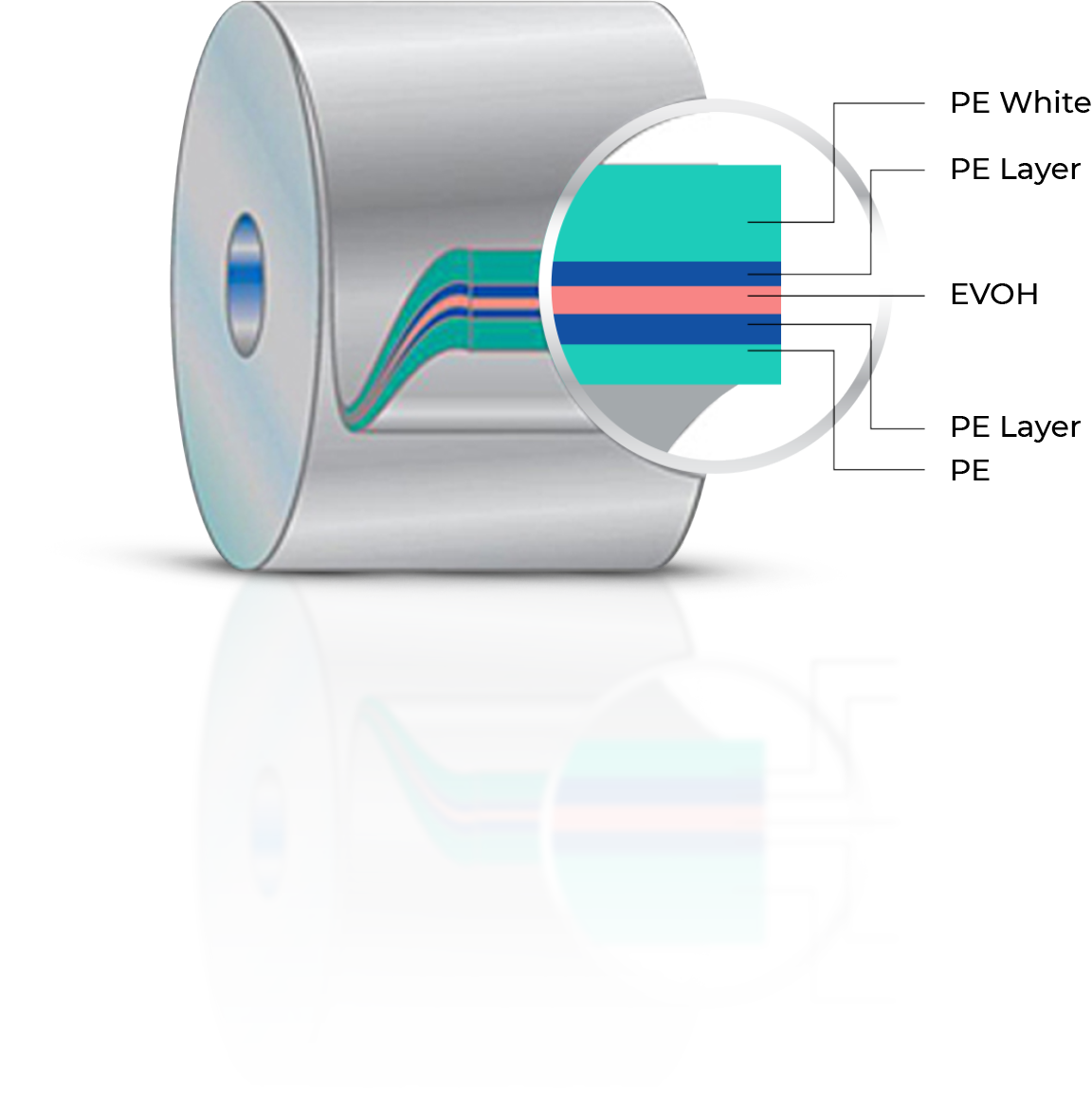

PLASTIC BARRIER LAMINATES (PBL)

PBL structures are a good option for packaging that needs to maintain its form and shape. It presents a more cosmetic look and is environmentally friendly. Special barriers can be provided such as EVOH (Ethylene Vinyl Alcohol Polymer) to offer strong chemical resistance. Standard material is offered in white or natural (clear) but specialty custom colours can also be developed.